Micro stepper motors have become an essential component in numerous precision applications, ranging from medical devices to robotics and industrial automation. At Shenzhen Jixin Micro Motor Co., Ltd, we specialize in the design and manufacturing of high-quality micro stepper motors that combine accuracy, reliability, and efficiency. This blog will take you through the design principles, production techniques, and quality assurance processes that make our micro stepper motors stand out in the market.

A micro stepper motor is a type of stepper motor that moves in very small steps, allowing for precise positioning and smoother operation. Unlike traditional motors, stepper motors do not rely on continuous rotation; instead, they advance in discrete steps, which can be controlled electronically. Micro stepper motors enhance this concept by dividing a single full step into multiple micro-steps, resulting in greater resolution and reduced vibration.

These motors are widely used in applications that require exact control of rotation angle or speed. From 3D printers and CNC machines to camera rigs and medical instruments, these motors power a wide range of precision devices. As technology advances, there’s a growing need for smaller, more efficient, and highly reliable micro stepper motors.

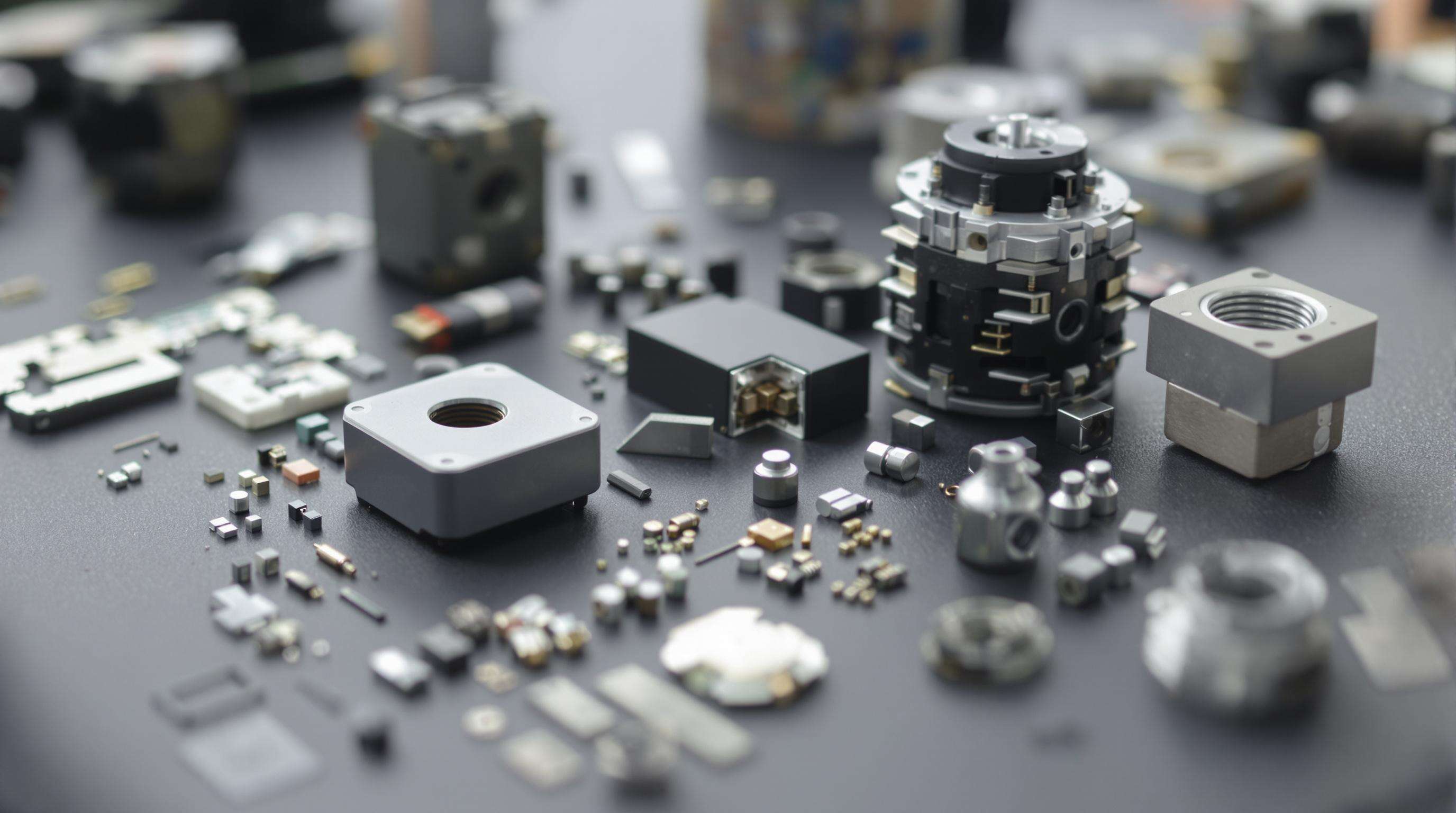

The design of a micro stepper motor involves careful consideration of electromagnetic principles, mechanical structure, and thermal management. At Shenzhen Jixin Micro Motor Co., Ltd, our engineering team begins by selecting high-quality materials, including magnets, copper wire, and precision steel, to ensure optimal performance.

The rotor and stator are precisely designed to optimize magnetic flux performance. The rotor is typically made with high-energy magnets that interact with the stator’s windings. The stator windings are carefully calculated to generate precise electromagnetic pulses, which control the rotation of the rotor in micro-steps.

Another key aspect of the design is the integration of bearings and shafts that reduce friction and wear. Our micro stepper motors often include miniature ball bearings, which ensure smooth rotation and extend the motor’s lifespan. Thermal management is also critical; we incorporate efficient heat dissipation structures to maintain stable operation under varying loads and speeds.

Once the design phase is completed, the micro stepper motor moves into production. The manufacturing process at Shenzhen Jixin Micro Motor Co., Ltd involves several key steps to guarantee accuracy and consistency:

Stator Winding: Precision winding machines are used to coil copper wire onto the stator core. Automated machines ensure uniform tension and alignment, which are essential for smooth motor operation.

Rotor Assembly: The rotor, including magnets and shaft components, is carefully assembled and balanced. Even slight imbalances can affect performance, so each rotor is tested for vibration and alignment.

Motor Assembly: Engineers precisely assemble the stator and rotor within the motor housing. High-precision jigs and fixtures are used, allowing the components to fit perfectly, which reduces mechanical noise and boosts efficiency.

Quality Testing: Every motor undergoes thorough testing, including electrical performance tests, torque measurements, vibration analysis, and thermal stability checks. Only motors that pass our thorough quality checks go forward to packaging and shipping.

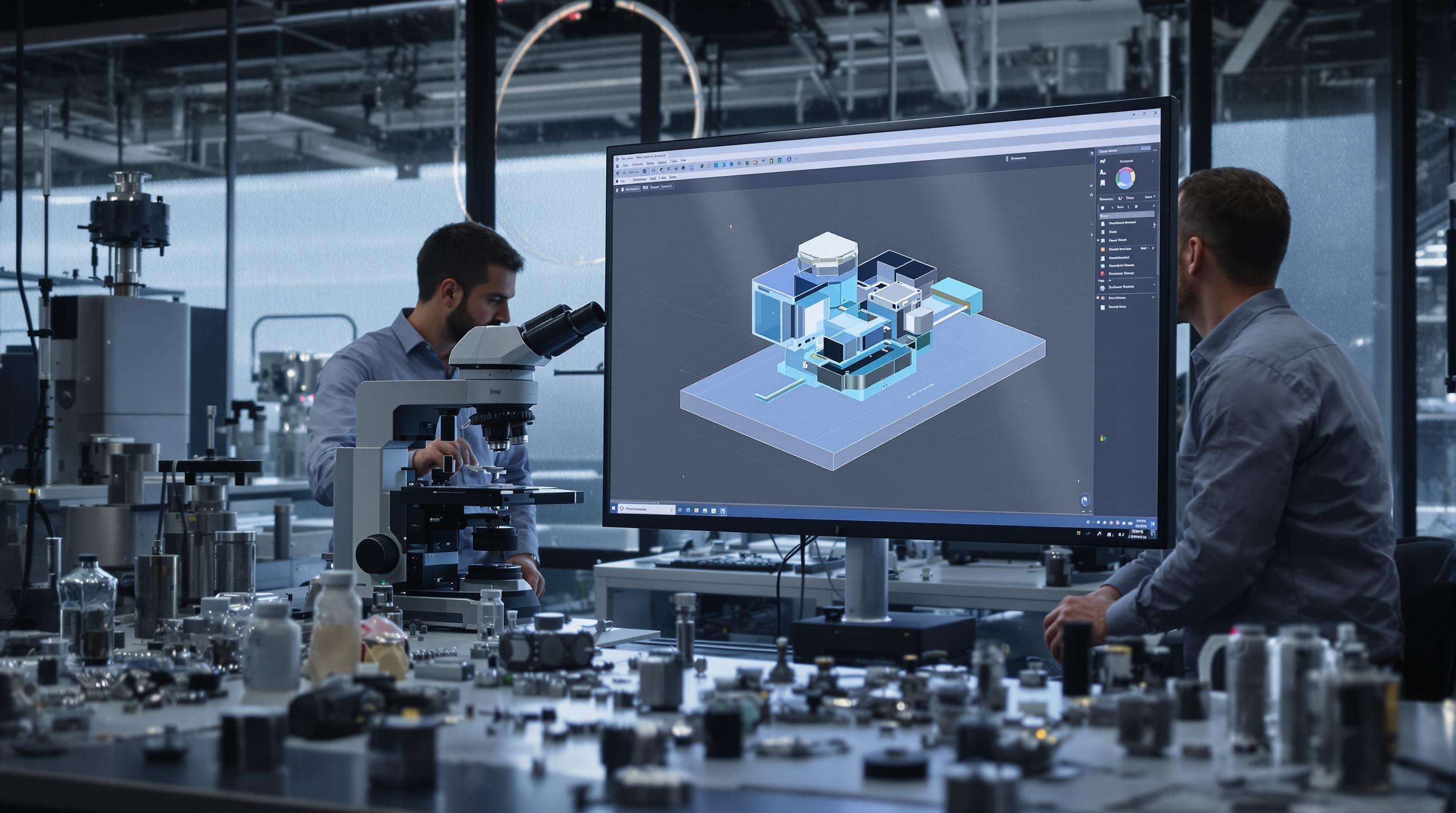

Quality assurance lies at the core of everything we do at Shenzhen Jixin Micro Motor Co., Ltd. Our production lines are equipped with modern inspection equipment that detects defects at every stage. In addition, our R&D team continually improves designs to meet the latest industry requirements and enhance performance.

Innovation is also important in the competitive field of micro stepper motors. We invest in research focused on materials, micro-fabrication techniques, and energy-efficient designs. This enables our motors to deliver higher torque, lower noise, and longer service life, meeting the demanding expectations of our clients worldwide.

Micro stepper motors have a wide range of applications due to their precision and reliability. In robotics, these motors help achieve precise joint movements and smooth, controlled motion. In medical devices, these motors help operate small instruments and pumps with precise control. Other industries, including 3D printing, automated assembly lines, and camera systems, rely on micro stepper motors for their compact size and fine control capabilities.

At Shenzhen Jixin Micro Motor Co., Ltd, we work closely with clients to customize motors for specific applications, making sure every solution meets their unique operational needs.

The design and manufacturing of micro stepper motors are complex processes that require expertise, precision, and dedication. Shenzhen Jixin Micro Motor Co., Ltd combines advanced engineering, high-quality materials, and thorough quality control to produce micro stepper motors that excel in performance and reliability. Whether for industrial automation, medical devices, or robotics, our micro stepper motors offer the precision and durability that modern technology demands.

2024 © Shenzhen Jixin Micro Motor Co.,Ltd - Privacy policy