Micro DC motors are widely used in modern electronic devices, from household appliances to industrial machinery. Understanding their efficiency and power consumption is essential for optimizing performance, reducing energy costs, and extending the lifespan of the motor. In this article, we explore the factors affecting micro DC motor efficiency, how power consumption is calculated, and practical tips to improve overall performance.

A micro DC motor is a compact, electrically powered device that converts electrical energy into mechanical motion. Unlike larger motors, micro DC motors are designed for applications where space, weight, and precision are critical. They are commonly found in drones, medical devices, robotics, and small household gadgets.

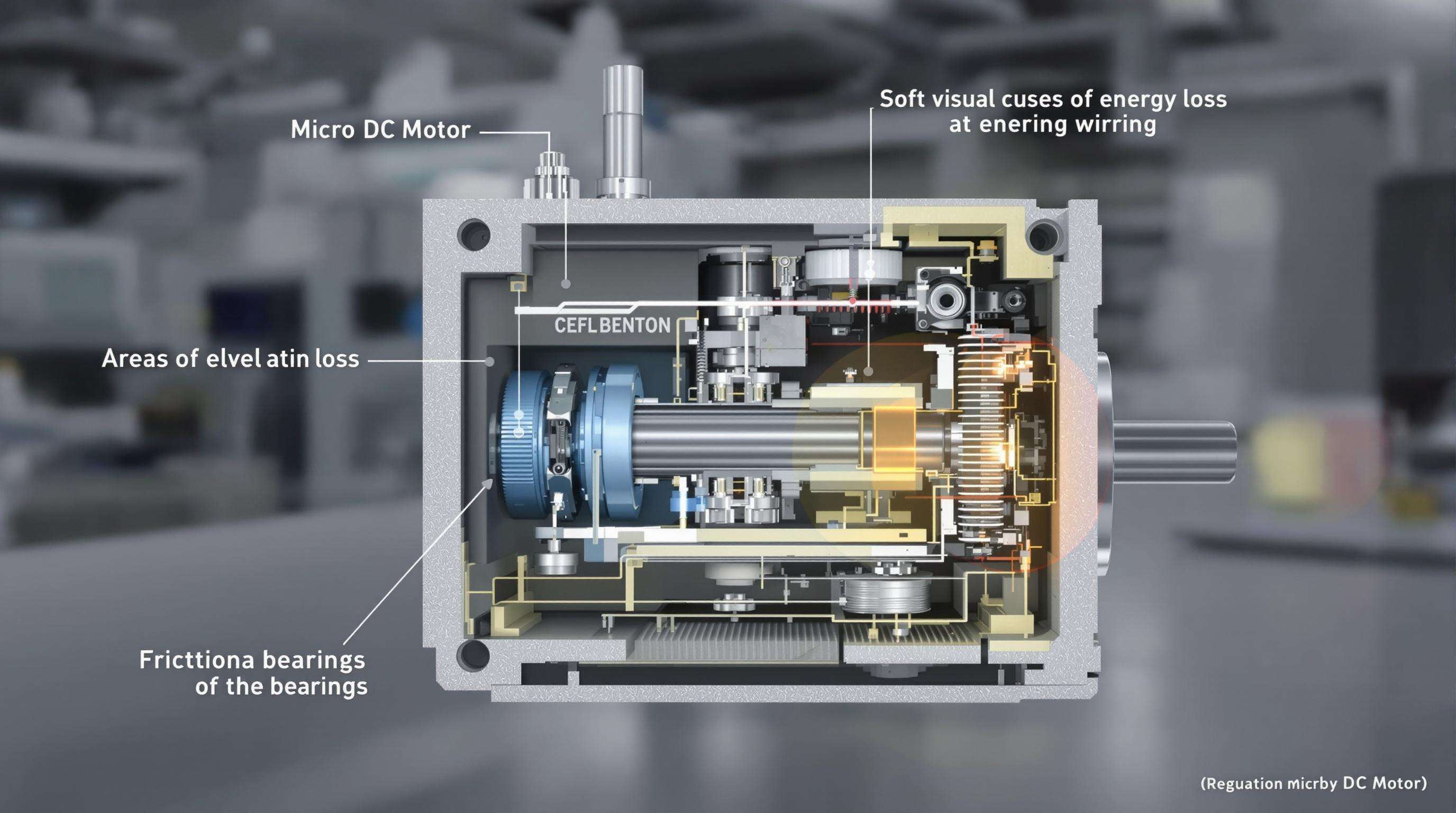

Despite their small size, micro DC motors follow the same fundamental principles as larger motors, with a rotor, stator, and magnetic fields working together to produce rotational motion. The design of these motors can vary based on the intended application, influencing both their efficiency and power consumption.

Motor efficiency refers to the ratio of mechanical output power to electrical input power. In simple terms, it measures how effectively a motor converts electricity into motion. Several factors influence micro DC motor efficiency:

Motor Design: The quality of the materials, rotor and stator design, and precision in assembly all impact efficiency. High-quality components reduce internal resistance and energy loss.

Load Conditions: A motor operating at its rated load tends to be more efficient than one running under very low or very high loads. Running a motor below or above its optimal load can lead to higher energy losses and excessive heat.

Voltage and Current Supply: Proper voltage and current ensure optimal motor performance. Using a supply that is too low may cause the motor to stall, while excessively high voltage can generate unnecessary heat and reduce efficiency.

Friction and Wear: Bearings and mechanical components create friction that reduces efficiency. Routine maintenance and adequate lubrication play a key role in minimizing energy waste.

At Shenzhen Jixin Micro Motor Co., Ltd, our micro DC motors are engineered with precision to maximize efficiency while maintaining durability. Innovations in winding design, magnetic materials, and compact bearings contribute to higher performance for a wide range of applications.

Power consumption is the amount of electrical energy a motor uses to perform work. For micro DC motors, power consumption can vary greatly depending on operating conditions and design specifications. It is generally calculated using the formula:

P = V × I

Where P is power in watts, V is voltage, and I is current.

Keep in mind that power consumption is not constant. Factors such as load changes, speed variations, and mechanical friction all affect how much energy the motor uses at any given moment. By monitoring power consumption, engineers can optimize motor performance, reduce energy waste, and select the right motor for specific applications.

Improving micro DC motor efficiency can lead to lower operating costs, reduced heat generation, and longer motor life. Some practical tips include:

Selecting the Right Motor: Choose a motor that matches your application's speed, torque, and load requirements. Oversized or undersized motors often operate inefficiently.

Optimizing Load: Operate the motor close to its rated load whenever possible. Avoid running motors at extremely low or high loads for extended periods.

Regular Maintenance:Keep the motor and its parts clean and properly lubricated for optimal performance. Minimize wear on bearings and reduce friction.

Voltage Regulation: Ensure stable voltage supply and avoid frequent voltage fluctuations that can reduce efficiency.

At Shenzhen Jixin Micro Motor Co., Ltd, our products undergo thorough testing to guarantee reliable performance. We provide detailed specifications for each motor, allowing engineers and designers to calculate power consumption accurately and plan for energy-efficient operation.

Micro DC motors are indispensable in modern technology, powering devices that require precision and compactness. Understanding their efficiency and power consumption is essential for engineers, designers, and end-users who aim to maximize performance while minimizing energy use.

By selecting high-quality motors, optimizing load conditions, and following proper operating practices, it is possible to greatly improve efficiency and reduce power consumption. Shenzhen Jixin Micro Motor Co., Ltd remains committed to providing reliable, high-performance micro DC motors that meet the growing demands of diverse applications worldwide.

2024 © Shenzhen Jixin Micro Motor Co.,Ltd - Privacy policy